Roof Seam Sealer

It may sound like a dangerous frat party activity, but roof flashing is simply the thin pieces of impenetrable material used to seal roof joints in order to prevent water damage. Thanks to the creation of sheet metal, our roofs can be covered in a multitude of joints, valleys, and seams without the home owner needing to compromise style.

Flashing Comparisons

Until the 1800’s, flashing carpenters resorted to a number of creative methods to reduce water penetration. Roof shingles were angled away from the joint and chimneys were placed at the ridge of the roof with steps built into the sides to throw off water. (Notes on Building Construction)

With the introduction of manufactured lead flashing, indoor mold problems were drastically reduced and designs began to branch out. Today flashing materials range from flexible products like rubberized asphalt, butyl rubber, and acrylic to the more structured metal flashings like, lead, aluminum, copper, stainless steel, zinc alloy, or coated metals such as galvanized steel.

Chemical interactions between the metal and its environment dictate which metal a roofer should choose. Aluminum and zinc flashing will corrode in contact to pressure treated wood. Aluminum will also react poorly to wet mortar or plaster. In coastal areas with salt spray, corrosion is accelerated so durable materials like stainless steel, copper, or galvanized steel are recommended. (Metal Roofing Magazine)

The appeal of copper is clear. It is malleable, durable, and corrosion resistant. It can be used with mortars and in hostile environments with a long service life. Flashing repairs can be expensive, but its durability makes copper, a relatively costly metal, a good financial decision. At Sheet Metal Caps we use 16 ounce (24 gauge) copper to craft our flashings and protect your home for many years to come.

Copper Flashing Installation

Yet we know that copper’s natural red-brown color and patina are not for everyone. Flashing can be hidden, or left intentionally exposed to add a rustic charm to your home’s façade, but if you like a silver finish, stainless or galvanized steel provide excellent alternatives. Whether you prefer sleek and modern stainless steel or the spangle of galvanized steel, we can craft resilient weatherproofing to meet your style. We use 26 gauge 304 stainless steel and 26 gauge galvanized steel handled with exam gloves so that you receive your flashings in pristine condition.

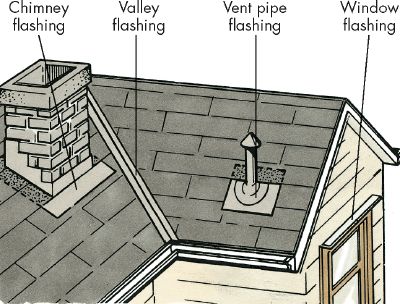

Photo courtesy of Green Building Adviser - http://bit.ly/1oX3zbl

There’s a lot of charm to this old brick house with its gable roof, but I’m rejoicing that modern day building techniques and materials allow for a range of different style homes to reflect each of our unique personalities. Now we can have skylights, vents, and chimneys placed where we like without concerns for the integrity of the roof.

As a final note, please be safe! Due to the danger involved, unless you are familiar with safe roofing practices, these projects are good ones to leave to professional contractors or roofing companies.

- Smith, Percy Guillemard Llewellyn. Notes on building construction. Part 1. London, Oxford and Cambridge: Rivingtons, 1875. Chapter 10, Plumbers work. Print.

- The glory of copper; Metal Roofing Magazine, December 2002/January 2003